Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Testing Report of The Oil Absorption Cotton Material

1.Testing Purpose

To do the contrast laboratory testing for the filtration life and pollutants holding capacity between HL PO-025 oil absorption material and another two contrasted oil absorption material

2.Samples Tested

Sample 1:Code:PO-025 (HL Filter Material)

Sample 2:Code: PP-025(Contrasted material-1)

Sample 3:Code: MFO(Contrasted material-2)

3. Testing Way

According to the HL Filter`s requirements of the filtration performance test. Take the oil absorption filter bag sample with disc (ф 50mm) is used for a single pass test of sewage, and record the change of filtration pressure difference until the pressure difference reaches 0.8bar, and the filtration life is obtained. After, the oil absorption material discs are dried and weighed, and the pollution capacity is obtained by subtracting the net weight.

Life = filter time when filter reaches replacement pressure difference (under experimental conditions)

4.Testing Data

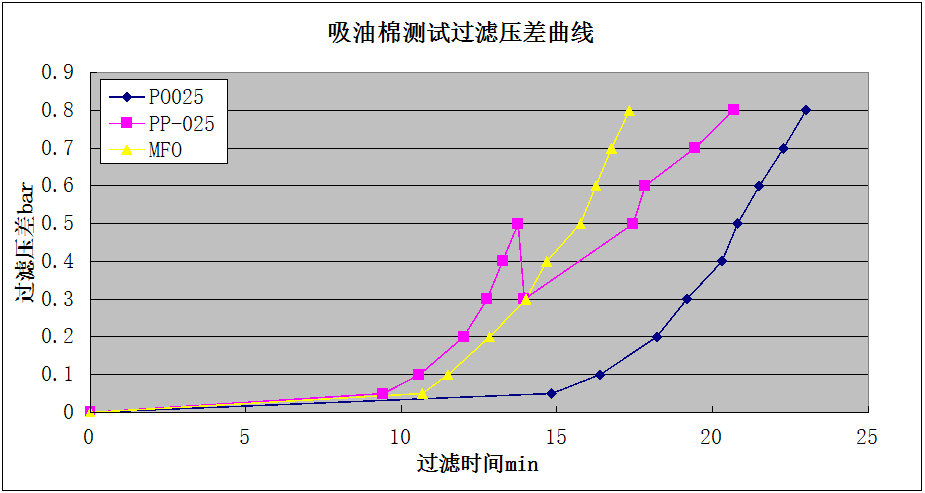

Comparison data of Sample 1 HL oil absorption material (PO025), comparison oil absorption material 2 (PP-025) and comparison oil absorption material 3 (MFO) are as follows:

| Item | PO025 | PP-025 | MFO |

| Filtration Life @0.8bar | 23.00min | 20.67min | 17.33min |

| Pollutants Holding | 4.48g | 3.25g | 2.18g |

| Pollutants Holding for Size 2 Filter Bags | 1.14Kg | 0.83Kg | 0.56Kg |

| The test was carried out at a filtration flow rate of 13m³/h/2# filter bag | |||

The filtration pressure difference change data is shown in the following table:

| PO-025 ΔP:bar/Time:min | ||||||||||||

| ΔP | 0 | 0.05 | 0.1 | 0.2 | 0.3 | 0.4 | 0.5 | 0.6 | 0.7 | 0.8 |

|

|

| Time | 0 | 14.8 | 16.4 | 18.2 | 19.2 | 20.3 | 20.8 | 21.5 | 22.2 | 23.0 |

|

|

| PP-025 ΔP:bar/Time:min | ||||||||||||

| ΔP | 0 | 0.05 | 0.1 | 0.2 | 0.3 | 0.4 | 0.5 | 0.3 | 0.5 | 0.6 | 0.7 | 0.8 |

| Time | 0 | 94 | 10.6 | 12.0 | 12.8 | 13.3 | 13.8 | 13.8 | 17.5 | 17.8 | 19.4 | 20.7 |

| MFO ΔP:bar/Time:min | ||||||||||||

| ΔP | 0 | 0.05 | 0.1 | 0.2 | 0.3 | 0.4 | 0.5 | 0.6 | 0.7 | 0.8 |

|

|

| Time | 0 | 10.7 | 11.5 | 12.8 | 14.0 | 14.7 | 15.8 | 16.2 | 16.8 | 17.3 |

|

|

5.Data Analysis

1). Compared with the laboratory conditions, the test life reached 111.11%, and the pollution capacity reached 137.85%. Similarly, the percentage increase of the pollution capacity was significantly greater than the percentage increase of the life. It is judged that the filtration efficiency of HL Filter oil absorption bag is higher than that of contrast Filter bags.

2).The pressure difference of HL oil absorption material (PO-025) and contrast oil absorbing material 3 (MFO) rose smoothly and did not fluctuate during the filtration process (see the filtration pressure difference curve below). The pressure difference of contrast oil absorbing cotton 1 (PP-025) fluctuated when the pressure difference was 0.5bar, indicating that the melt-blown structure stability was poor and there was the possibility of material leakage.

6.Testing Result

HL Filter oil absorption material (PO-025) has relatively high pollution capacity and filtration efficiency, and good structural stability, which can make the filter bag processed in relatively high filtration accuracy with a long filtration life.

Note: However, the test results are only for the test of samples under laboratory conditions, and the actual service life and pollution capacity are determined by the transmission conditions and the particle distribution of filtration

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.